In our daily communication with international clients, one common question we receive is:

“This bottle looks common—why do we need to make a new mold?”

“We are here to buy glass bottles, why do we need to buy moulds?”

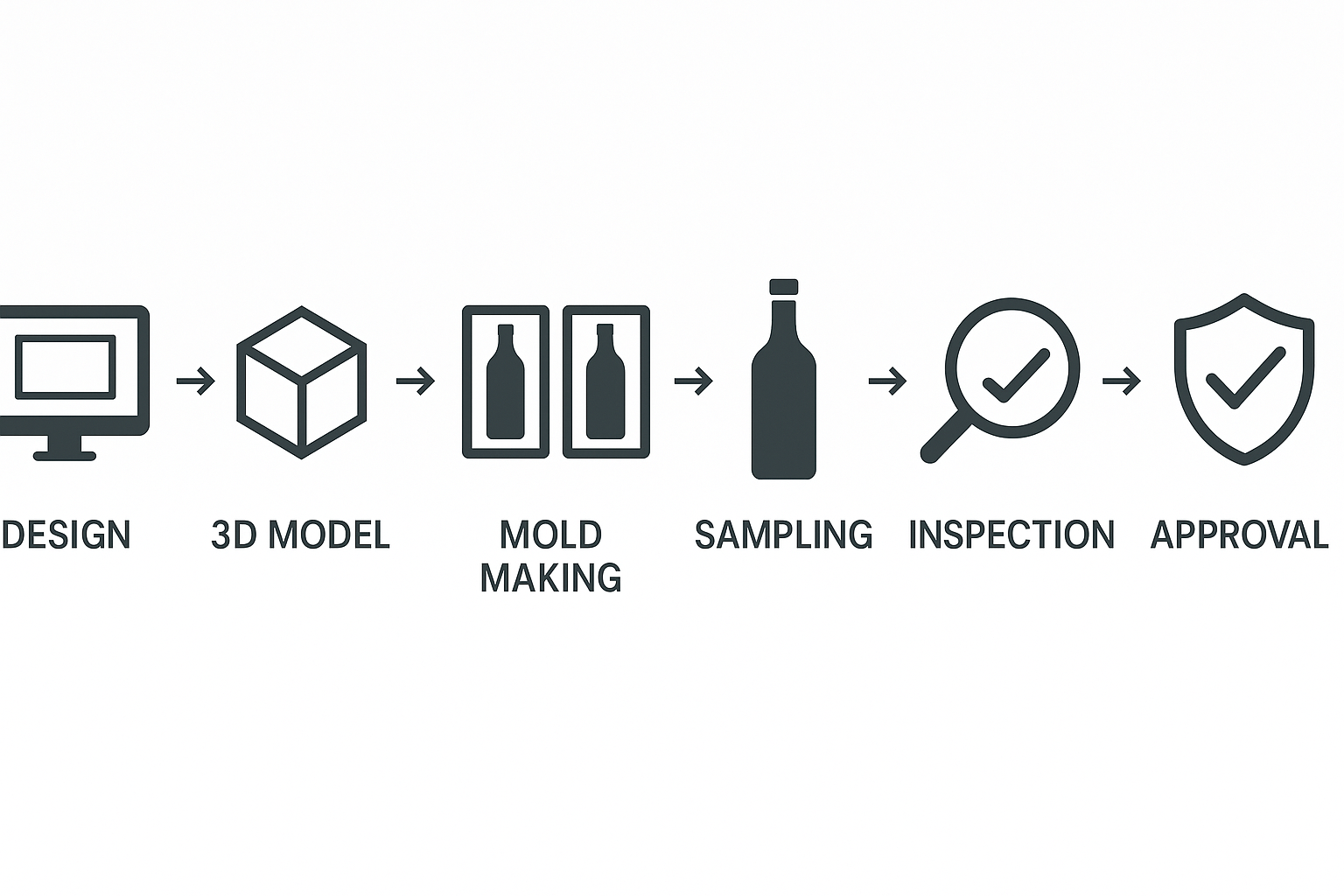

While it may seem simple on the surface, mold-making for glass bottles is a highly technical and precise process that often requires customization based on various factors. Here’s why a new mold is sometimes necessary—even for bottles that look familiar:

1. Different factories use different equipment

Each factory has specific molding machines and mold standards. Even if two bottles look similar, the connection design, cooling groove, mold size, and machine compatibility can vary greatly and require a dedicated mold.

2. Clients have unique dimensional requirements

Small differences in neck diameter, thread structure, labeling surface, or base thickness can affect how the bottle fits with filling lines, capping machines, or labeling systems. Custom molds ensure functionality.

3. Branding requires exclusive customization

For bottles with embossed logos, unique shapes, brand icons, or decorative patterns, creating a brand-specific mold is the only way to accurately reproduce the design.

4. Material or capacity changes need structural adjustments

Bottles with different weights, wall thickness, or bottom designs (like deep punt vs. flat base) require changes in the mold structure to maintain durability and production success rates.

5. Molds may be private property of other clients

Even if a similar bottle is on the market, its original mold may be owned by another client. To protect intellectual property and ensure exclusivity, factories will not reuse or copy those molds.

Glass bottle mold-making is not just a manufacturing step—it’s part of ensuring product accuracy, reliability, and brand identity. When we recommend opening a new mold, it reflects our commitment to professional quality and long-term cooperation.

Still have questions about mold development? Contact us for evaluation—we’re here to provide efficient, transparent, and professional mold solutions tailored to your product.