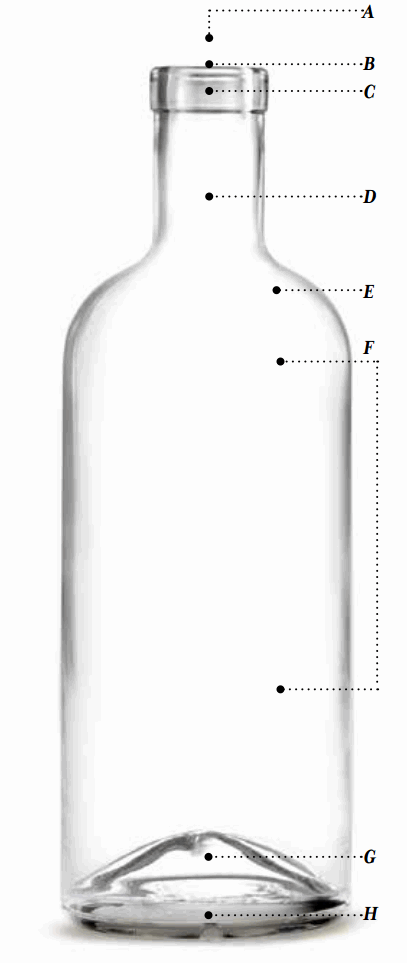

A. Through Bore – This refers to the minimum neck diameter for ease in bottling. A fill tube must typically be at least 1mm narrower than the through bore. For example, if a through bore is 16.5 mm, then the fill tube is recommended to be 15.5 mm. Normal filling tubes are 15 mm or larger.

B. Bore – This term refers to the dimension at the very top opening of the bottle and tells the bottler what size cork should be used for the best seal. Standard bore for the U.S. is 18.5 mm (0.728 inch). Many larger-necked spirits bottles use 21.5 mm (0.846 inch) or larger. The length of the bore inside of the neck is important for ensuring proper cork sealing.

C. Bottle Ring – Sometimes called the bead, this is the flared top section of the bottle. A seam on the lower edge of the ring shows where this part of the mold is joined to the body mold. The bottle ring can be interchanged with a compatible body mold.

D. Bottle Neck – This part of the bottle takes on a difficult task when air is blown into the bottle. It must be straight inside and out, creating a controlled cylinder for the cork to fit in. A thin neck takes a smaller diameter cork, while a fat neck will require a larger cork.

E. Shoulder – The widest part at the top of the body, just below the neck. If embossing is used, it is usually applied here because this area has no bottle-to-bottle contact point when bottles stand side-by-side.

F. Label Panel – The bottle blueprint shows the location and size of the label panel. Designers should use this reference to ensure the label fits on this flat area.

G. Punt – This pushed-up area is a traditional addition to the bottle. It has no real use in current glass making, but some consider a deep punt to be an indication of quality. The punt can add height to a bottle by taking up volume in the base, and can be customized.

H. Base – The bottom of the bottle has a base plate where the base attaches to the body mold. This area can be customized.